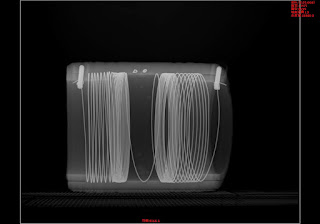

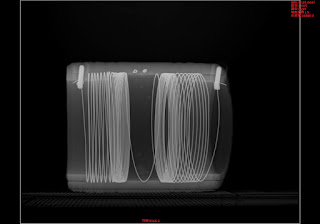

In addition to welds Portable DR actually has more applications,hatatest

In addition to welds Portable DR actually has more applications. 1.#HATATEST Portable DR system have huge related experience--electric power,Automobile,High-speed rail,casting,rubber,Aeronautics,Military ,Architecture...... 2.HATATEST Portable #DR system support dynamic imaging --Image quality can be seen before exposure,Dynamic superposition, image clearer 3.Software with some powerful function 4.Technology make our cost more Competitive,around 30% lower cost 5.#HTJW series flat panel detectors can be used with corresponding radioactive sources like SE75 or IR192 6.Privately customized, online automatic radiographic testing system 7. CE certification peng@hata-ndt.com