Five principles of conventional non-destructive testing —— #Principle of magnetic particle detection

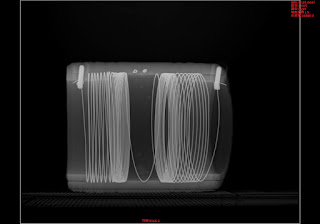

# Magnetic particle detection is to magnetize (integral magnetization or local magnetization) by applying a magnetic field to the workpiece to be inspected, and a magnetic field line will escape from the surface of the workpiece at the surface and near surface defects of the workpiece to form a leakage magnetic field, which can be adsorbed by the presence of magnetic poles. The magnetic powder applied on the surface of the workpiece forms an aggregated magnetic mark, thereby showing the presence of defects. Magnetic particle testing methods are widely used to detect defects on the surface or near surface of magnetic materials. Used to detect welds, castings or forgings such as valves, pumps, compressor components, flanges, nozzles and similar equipment. To detect defects on a deeper inner surface, a radiographic or ultrasonic test is required. The #yoke is one of the commonly used tools for magnetic particle inspection. At present, ordinary yokes (external power supply and light...